ELECTROPLATING

There are 3 basic steps to vinyl production.

The manufacturing process for records has remained largely consistent since its inception, although the specifics of transferring recorded audio onto a 12-inch disc and positioning it beneath your turntable can still be confusing. Let's explore the three stages involved in the vinyl production process, with the last two being services we handle internally!

We have Lacquers, now plating…

Plating, or electroplating, is the process of creating metal parts, or stampers, from master lacquers for the replication of vinyl records.

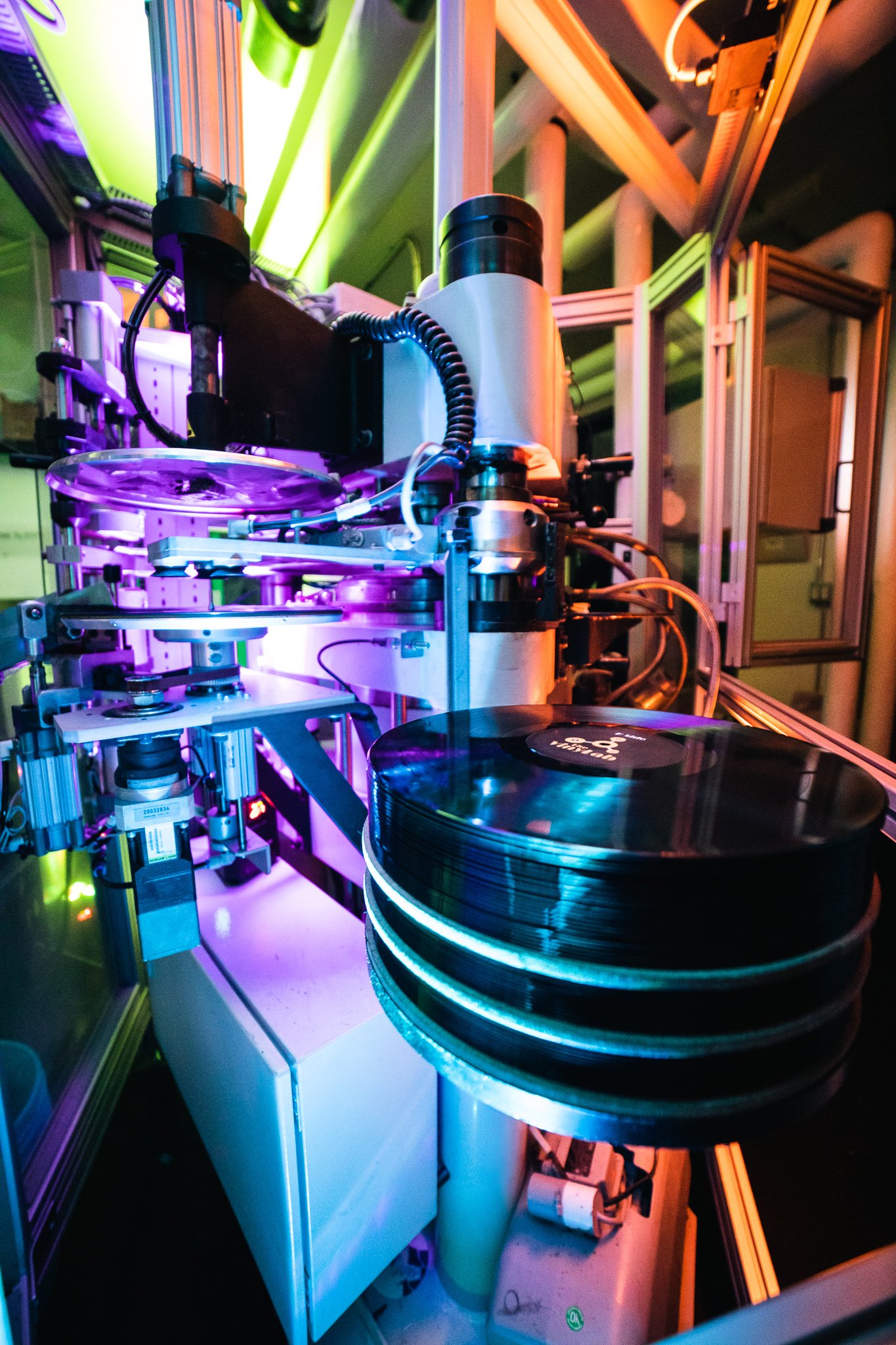

Once the lacquers are ready to go, they are cleaned and sprayed with a thin layer of silver and then placed into a series of electroplating baths.

Silvering

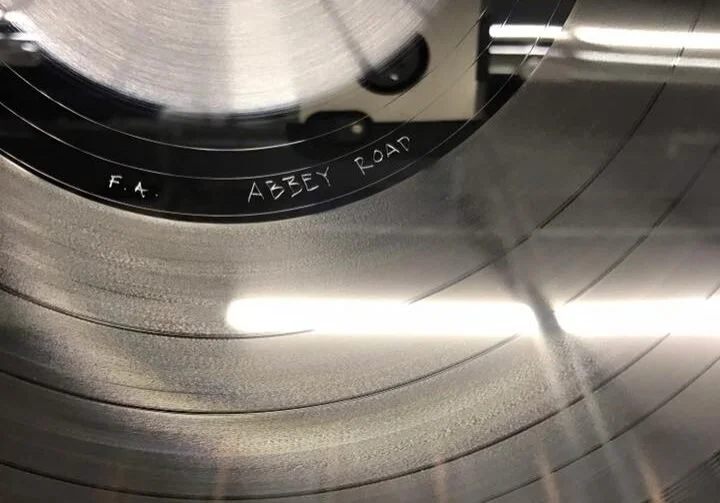

At this stage, the lacquer is destroyed once the metal stamper is pulled off of it. Now we have a negative copy of the lacquer, which is called the father. From here, we use the father to make a mirror copy of itself in a similar way we used the lacquer to make the father. This is called the mother. If you want to think about it in terms of 3rd grade biology, the father has ridges and the mother has grooves.

Father

Mother

Since the mother is a negative of a negative, it’s essentially an exact copy of the lacquer, but made of metal. It is often played back on a turntable in order to check for any impurities on the before moving on.

This process involves using an electrically charged nickel solution to transfer metal onto the surface of the silvered lacquer. It’s done in two stages: the first is building up a base layer on the disk at a lower amperage (current), and the second is thickening up the plate at a higher current to the desired thickness.

Nickle Bath

Once the father and mother have been made, the mother is cleaned and then plated to create stampers. These are similar to fathers in that they are negative copies of the lacquer and have ridges. Stampers are sent to the pressing plants and are used to actually stamp out, or press, vinyl records. From the father we can create 3 mothers, and from each mother, 5 stampers. And each stamper can be used to make 500-1000 vinyl records!

Stampers

Ready to place an Electroplating order? Fill out the form below!

Electroplating Order Form.

Please enter the details of your order in the form below.

All orders are 10-day turnaround unless noted in the “Any Additional Information” section below.

The Vinyl Lab also offers 5-day, 3-day, and 1-day turnaround options for additional costs.